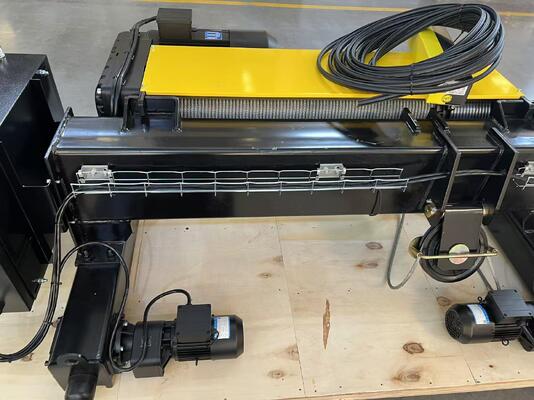

European Type Hoist EOT Overhead Bridge Crane

European Type Hoist EOT Overhead Bridge Crane with Electric Wire Rope Hoist for industrial overhead crane applications.

Product Introduction

The structural design of the European-style double-girder bridge crane revolutionizes traditional "heavy structure, large size" models by achieving lightweight construction through material optimization and structural simplification while maintaining load-bearing stability.

Key Design Features

- Main Beam and End Beam: Thin-walled profiles with modular splicing. Main girder utilizes box-shaped thin-walled welded structure (Q355B material) with web thickness reduced by 15%-30% compared to traditional cranes. Finite element analysis optimizes stress distribution, reducing overall weight by 20%-40% while ensuring torsional and bending resistance.

- End Beam Construction: Standardized profile splicing (H-beam or square tube) replaces traditional cast steel components, resulting in lighter weight and higher assembly efficiency. High-strength bolt connections facilitate transportation, on-site assembly, and future maintenance.

- Hoisting Mechanism: Integrated European-style wire rope hoists with compact structure (30%-50% smaller volume than traditional winch mechanisms). Lightweight trolley frame made of aluminum alloy or high-strength steel features low wheel pressure (20%-30% reduction), decreasing load on main beam and factory infrastructure requirements.

Applications

Ideal lifting equipment for factories, mines, agriculture, electric power, construction sites, docks, and warehouses for machine installation, cargo lifting, and truck loading/unloading operations.

Product Features

- High working efficiency with excellent performance, safety, and reliability

- Smooth movement and comfortable operation

- Convenient maintenance and aesthetic painting

- Compact structure with light deadweight and reduced wheel load

- Efficient transmission and power source

- Customized design and manufacturing according to specific requirements

Technical Specifications

| Capacity (t) |

Working Class |

Lifting Height (m) |

Lifting Speed (m/min) |

Running Velocity (m/min) |

Rope Reeving |

| 10 |

M5 |

6 |

5/0.8 |

2-20 |

4/1 |

| 9, 12, 15, 18 |

M5 |

9 |

4/0.67 |

2-20 |

4/1 |

| 16 |

M5 |

8 |

2.7/0.45 |

2-20 |

6/1 |

| 32 |

M5 |

6 |

0.53/3.2 |

2/20 |

12/2 |

| 50 |

M5 |

9, 12, 12 |

- |

- |

- |

Main Components

Company Overview

Related Products

Company Certifications

Frequently Asked Questions

What types of cranes do you offer?

As a manufacturer with over 15 years' experience, Rui Cheng provides a range of cranes, including gantry cranes, overhead cranes, electric hoists, jib cranes, and customized lifting solutions tailored to specific industry needs such as steel, precast concrete, and container handling.

How do I know which crane is suitable for my project?

Our team of experts is here to help! By understanding your lifting capacity requirements, operational environment, and usage frequency, we can recommend the ideal crane solution for your project. Contact us for a free consultation.

How to choose the right crane?

The following factors need to be considered when choosing a crane: Load capacity, Lifting height, Working environment, Frequency of operation.

What maintenance services do you offer?

We offer comprehensive maintenance plans, including preventive maintenance, inspection, repair, and spare parts replacement, to keep your crane running efficiently and safely. Our service team is available for scheduled and emergency support.

Can you accept OEM?

Yes, of course. Any logo is acceptable. Material, color, size, packing, brand, delivery, etc.

What are your delivery and installation timelines?

Delivery and installation timelines vary based on the type and customization of the crane. Generally, standard cranes can be delivered within 6-8 weeks, while customized solutions may require additional time. We aim to provide accurate timelines upfront to ensure smooth project planning.

Do you offer installation services?

Yes, we provide comprehensive training programs for crane operators, including safety training, maintenance guidelines, and operational best practices to ensure your team is fully prepared to operate the crane safely and efficiently.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!